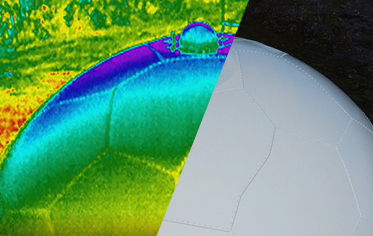

Thermographic Inspection Services

Thermal imaging provides the ability to see in complete darkness; measure temperature remotely; and see through obscurants such as smoke, dust and light fog. This gives the unique ability to see minute temperature variances – normally invisible to the naked eye. ITI has adapted this capability to inspect a variety of structures and identify occurrences of:

- Composite Panel Delamination

- Moisture penetration

- Insulation voids

- Air infiltration

- Air exfiltration

- Window and door seal leakage

A thermographic inspection identifies and quantifies problem areas in a structure and allows maintenance and repair teams to focus on damage sources and solutions. Inspections are performed by hand (walking inspection) or by air via UAV/Drone.

Corrosion Inspection Services

Corrosion control is key to the sustainment of deployed equipment assets. ITI recognizes a corrosion management program requires early detection and assessments for successfully managing maintenance actions. Our team has the experience necessary to identify and predict corrosion issues for a wide variety of equipment located in worldwide climates. ITI performs on-site inspections using various NDI equipment and techniques in conjunction with equipment maintenance prediction models and algorithms to assess the longevity of fielded assets.

Configuration Audits

ITI has provided Physical Configuration Audit (PCA) services for DoD programs to verify related design documentation (manuals and drawings) matches the Configuration Item (CI) as specified. Our team also confirms that the manufacturing processes, quality control system, measurement, test equipment, and training are adequately planned, tracked, and controlled. The audit validates many of the supporting processes used in the production of the item and assess identified impacts post System Verification Review and post Functional Configuration Audit (FCA).

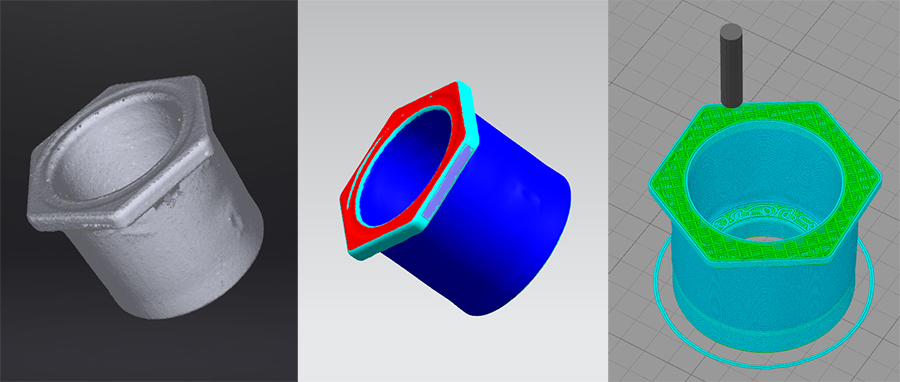

3D Part Scanning

3D laser scanning is the process of converting physical objects into precise point cloud data. This data can be leveraged to develop digital models enabling you to quickly and accurately capture your object’s shape and geometries. This process provides a complete digital representation of an object to be used for 3d printing, rapid prototyping, reverse engineering, quality inspection, tool design, and tool path development. ITI’s 3D scanning services include:

- 3D printer ready model generation (3D scan to water-tight STL model)

- Reverse engineering CAD model (3D scan to CAD model)

- Quality Control Assessment (3D scan comparison to existing CAD model)

- Complete Dimensional Inspection of 3D scan to Blueprint

- Quality Inspection of parts, with or without a CAD Model

- Detailed Inspection Reports

- 3D CAD Modeling from Blueprints

- Rapid prototyping through 3D printing for fit tests