A radome riser or ring beam allows the mounting surface of the radome to be level with a uniform height. Typical risers/beams come in galvanized steel, powder coated steel.

Calcium hydroxide, sodium hydroxide, potassium hydroxide, and other components contribute to a high pH value that is often well in excess of 12 (1). At these high concentrations, hydroxylates dissolve the surface of materials that are in direct contact with it, including both metals and many composites. Traditional polyester resin fiberglass, for instance, has shown(2) observable mass loss after just 100-hour exposure to a concrete pore solution. For a permanent installation, such degradation could lead to catastrophic failure of the mounting points.

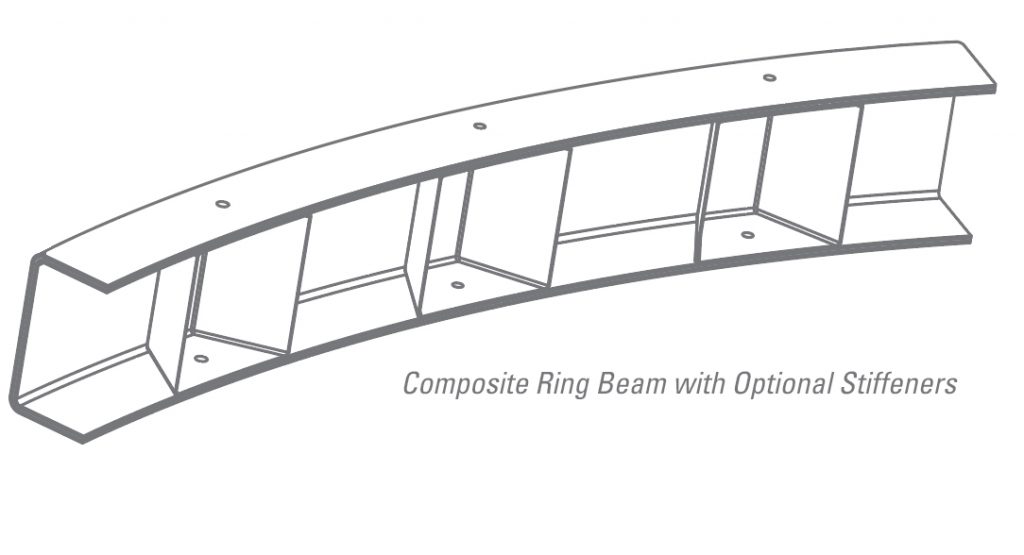

ITI has developed a composite Alkali safe Riser solution. The beam is fabricated from a structural "H" or "W" shape with optional internal gussets to provide additional structural support if required. The beam is designed to interface with existing radome base flange and foundation architecture. Due to its extreme alkali and corrosion resistance, the ring can be embedded in the foundation concrete.

(1) “Don’t be ‘Burned’ by the Alkalinity of Concrete,” Concrete Construction, June 2004

(2) Effects of Environmental Exposure on Fiber-Reinforced Plastic (FRP) Materials Used in Construction, Chin, Nguyen, and Aouadi.