Knowledge, innovation, and proven expertise have aided ITI-RCS in becoming a leading provider of engineering support services. Our full-spectrum engineering solutions cater to various industries including government, defense, communications, recreation, and entertainment.

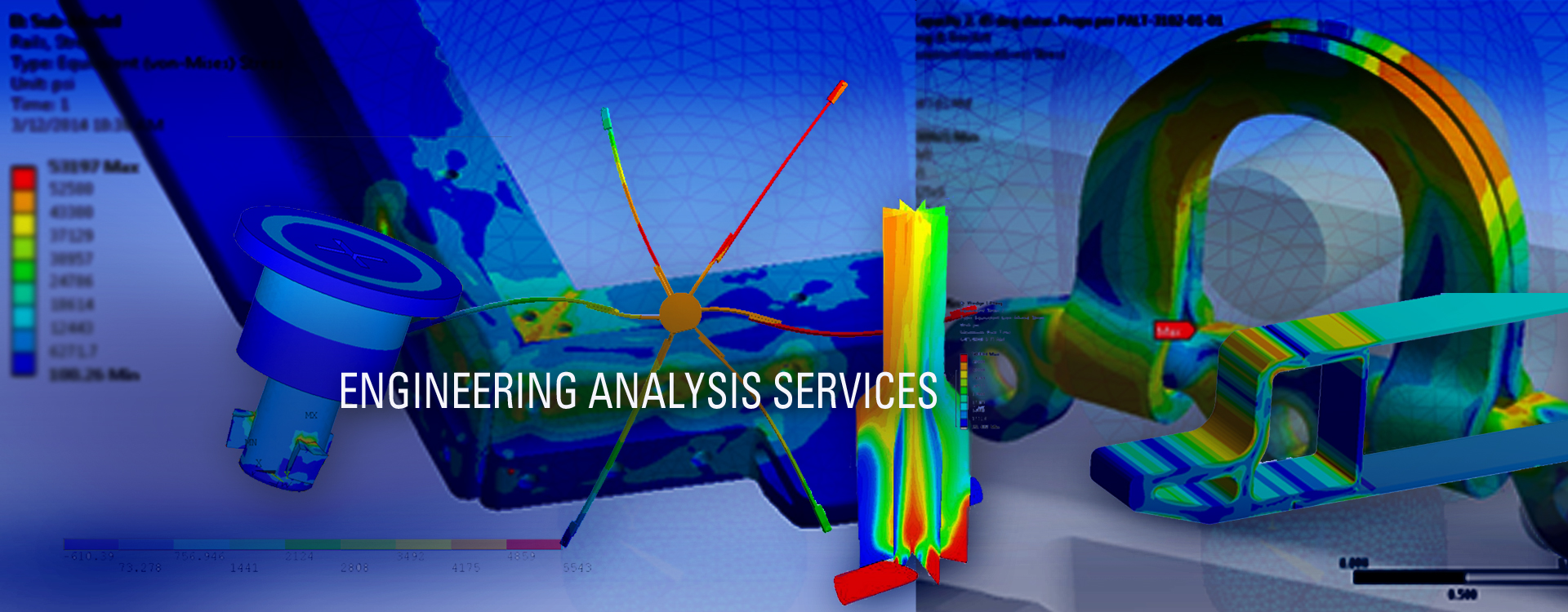

We provide excellent-value, professional engineering analysis services including: stress analysis, computational fluid dynamics (CFD), thermal analysis, and radio frequency (RF) analysis. Such capability reduces the development time as well as cost. Our team of experienced engineers is dedicated to providing our customers with the highest quality products and services.

STRUCTURAL ANALYSIS

ITI uses a three-pronged approach to structural analysis. First, sophisticated Finite Element Analysis (FEA) is used to predict structural behavior. Second, when possible analytical solutions are obtained to verify the results of the FEA. Third, mechanical testing is performed to validate the FEA and analytical solution accuracy. This process ensures that ITI’s designs perform as expected. We ensure that every design is able to cope with unforeseen circumstances. A minimum safety factor of 2.0 is used in all designs. When desired or required, a higher safety factor can be provided. Large safety factors ensure that every product performs as designed despite material inconsistencies, manufacturing inconsistencies, shipping and handling damage, and other forms of abuse that may occur. Structural engineering involves advanced engineering concepts and high standards of application; our team delivers on challenging requirements.ITI can perform structural analysis for the following:

- Composite (fiberglass/carbon fiber) structures

- Steel, aluminum, and plastic parts

- System/Connection assemblies

- Steel structures

- Concrete structures

ITI can also provide analysis for parts, systems, and buildings including:

- Stress analysis

- Buckling analysis

- Geometry optimization

- Vibration analysis

- Seismic analysis

- Foundation analysis

COMPUTATIONAL FLUID MODELING

Fluid dynamics is rapidly becoming a critical factor in modern design applications. ITI’s computational fluid dynamics (CFD) capabilities provide detailed insight into the complex physics of your product. We use an analysis-driven approach to design, capturing the influences of fluid flows on both structural and thermal components early in the design process. We then use that insight to optimize your product, thus eliminating wasteful late cycle design modifications and reducing costly testing. Throughout the process we commit to a high level of technical excellence and providing you with a quality product.- Steady state and transient flows

- Laminar and turbulent flows

- Fluid mixing

- Multi-phase flows

- Porous media

- Buoyancy

- Radiation heat transfer

- Conjugate heat transfer

- Sliding interfaces

- Incompressible and compressible flows

- Newtonian and non-Newtonian flows

- Phase change

- High and low speed flows

We can provide analysis for applications including:

- Large structures such as towers and radomes

- Pipe flows

- Mixing vessels

- Aerodynamics

- Micro components

- Electronic cooling

- HVAC

- Coupled fluid-thermal-structural systems

THERMAL ANALYSIS

Thermal analysis and design has become a critical consideration in many modern engineering applications. Understanding and controlling thermal influences can mean the difference between success and failure for both individual components and complex systems. ITI’s analysis-driven approach to design provides the insight necessary to ensure success. Our physics based analysis aims to identify design issues early and guide your product to an optimized configuration. Whether your application is simple or complex, ITI commits to provide you with a high level of technical excellence and quality.Our Thermal Modeling capabilities include:

- Steady state and transient heat transfer

- Nonlinear conduction

- Natural convection

- Forced convection

- Radiant heating and cooling

- Surface to surface radiation exchange

- Phase change

- Conjugate fluid heat transfer

- Thermo-structural interactions

We can provide analysis for applications including:

- Solar exposure

- Micro components

- Electronic cooling

- High temperature materials

- Thermal degradation of structural components

- Thermal cycling

- Engine thermal management

- Aerospace applications

- Coupled fluid-thermal-structural systems

RADIO FREQUENCY (RF) ANALYSIS

ITI approaches each new radome order with a thorough review of the customer requirements. With an understanding of the customer requirements, the level of analysis required for each order is determined. Analysis starts with modeling of the physical material properties and the physical dimensions of the proposed materials to estimate the effects of the radome on the radar system’s performance. Most applications are a trade-off between mechanical properties and electromagnetic effects, so some level of optimization is necessary. To validate that a particular design meets user requirements, ITI uses a number of levels of analysis including:- Flat panel loss as a function of incident angle and the radome sandwich selected

- Radome-shaped panel loss estimates

- Simulated antenna Far Field Radiation pattern

- Simulated antenna Far Field Radiation pattern including seam effects

- Full-wave characterization of joint or other structural aspects